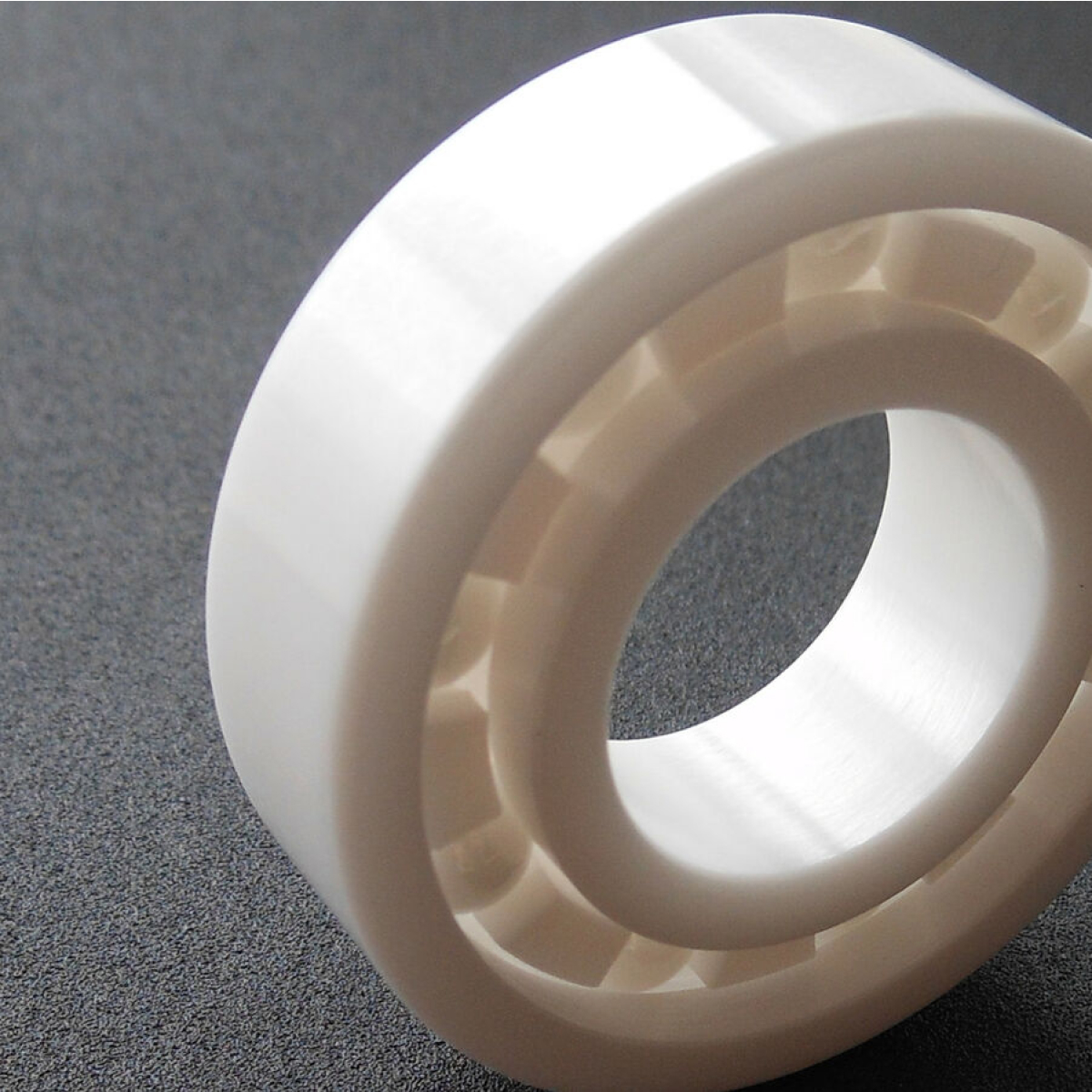

Zirconium Dioxide

Zirconium Dioxide (ZrO2), commonly known as zirconia, is a versatile ceramic material recognized for its impressive mechanical properties and chemical stability. Its high toughness and wear resistance make it suitable for various demanding applications in both structural and functional roles.

Industrial Applications

Thermal barrier coatings in jet engines, using its low thermal conductivity to protect engine components from extreme heat.

High-precision lenses and optical components, taking advantage of its transparency and high refractive index.

Fuel cell components and thermal insulation materials in renewable energy systems, where its chemical stability and thermal insulation properties are critical.

Material Properties

Density

5.68–6.1 g/cm³

Hardness

8.0 (Mohs scale)

Thermal Conductivity

2–3 W/m·K

Thermal Expansion

10–11 ppm/°C

Electrical Resistivity

10¹⁰–10¹² ohm·cm

Fracture Toughness

6.0–10.0 MPa·m¹/²

Flexural Strength

900–1200 MPa

Our Production Technologies

Our sustainable production technologies and advanced ceramics set us apart, offering unparalleled protection and performance in the defense industry. We focus on delivering solutions that enhance safety while maintaining efficiency and reliability.

Sustainable Quality

KIM Technologies offers a complete range of services—from evaluation and design to manufacturing and integration—ensuring top-tier support at every stage. Our expertise covers ballistic materials, armor systems, and cutting-edge logistics support.

- Evaluation: All evaluations are completed in our fully equipped labs under one roof with consistent quality.

- Design & Simulation: We perform ballistic, conceptual, compliance, and human factor engineering analysis.

- Manufacturing: All ceramics are produced in-house, ensuring compatibility across the value chain.

- ILS: We offer full support in ILS management, including MTA, FMECA, and RCM.