Quality Assurance

KIM Technologies operates a robust and efficient quality management system that is customer-focused and driven by continuous improvement. We collect and analyze performance metrics to enhance both operational and organizational outcomes. To ensure customer satisfaction, we implement quality control at every stage of production, starting with raw material inspections, and take a preventive approach to avoid errors.

Sustainable Quality

We adopt sustainable quality as our main production principle. In order to realize this principle, we respond to our customers’ needs by starting from the quality control of raw materials, supporting all relevant production processes with line and end-of-production quality controls.

Raw Material Procurement

- Initial quality check on raw materials.

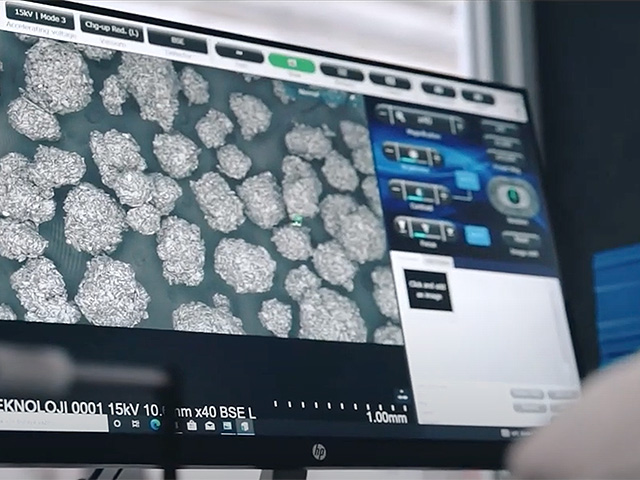

- Laboratory testing of raw materials.

Line Quality Controls

- Test productions before mass production.

- Detailed inspections during production, including molecular and crack examinations.

Mass Production & Retesting

- Ballistic lab testing

- Random sampling and retesting during mass production.